新入荷再入荷

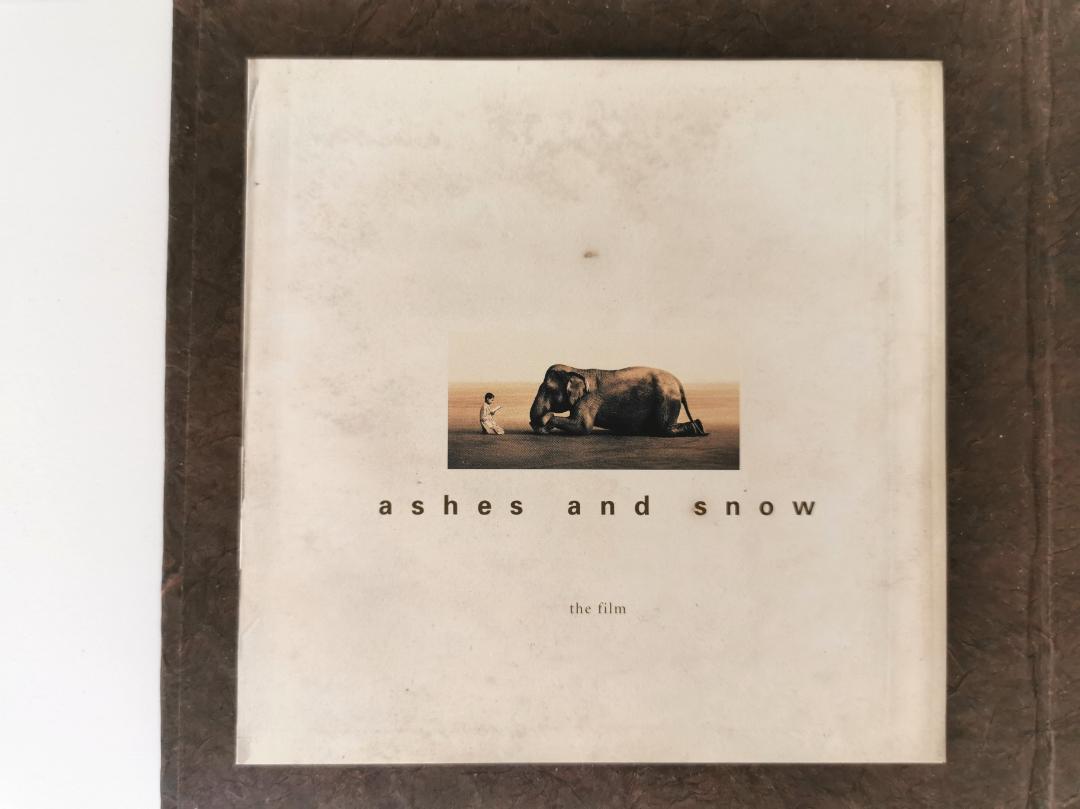

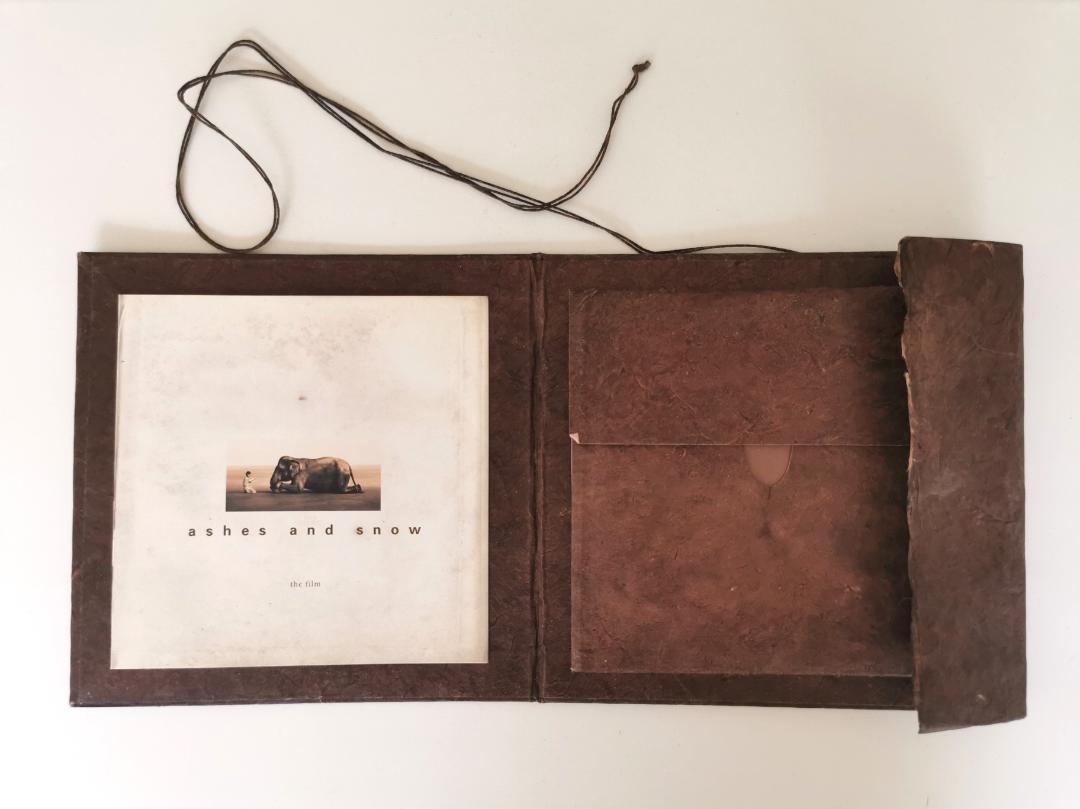

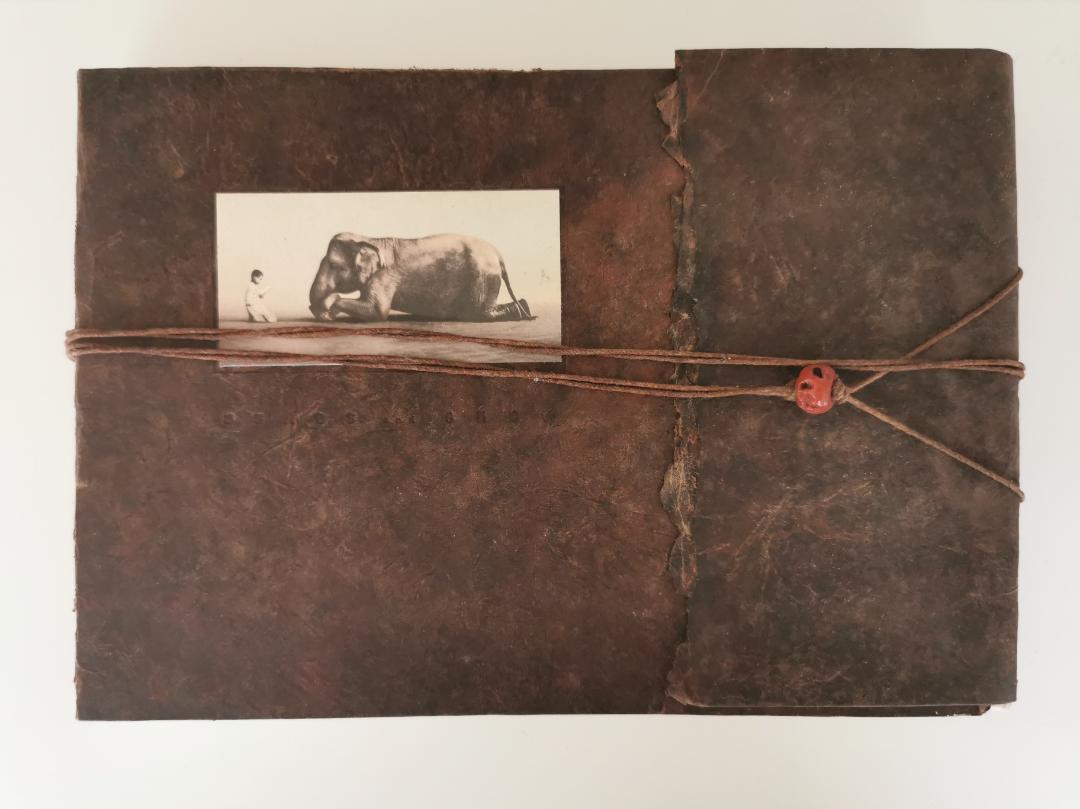

グレゴリー・コルベール Ashes and Snow 写真集・DVD

タイムセール

タイムセール

終了まで

00

00

00

999円以上お買上げで送料無料(※)

999円以上お買上げで代引き手数料無料

999円以上お買上げで代引き手数料無料

通販と店舗では販売価格や税表示が異なる場合がございます。また店頭ではすでに品切れの場合もございます。予めご了承ください。

商品詳細情報

| 管理番号 | 新品 :68309851 | 発売日 | 2025/01/11 | 定価 | 10,800円 | 型番 | 68309851 | ||

|---|---|---|---|---|---|---|---|---|---|

| カテゴリ | |||||||||

グレゴリー・コルベール Ashes and Snow 写真集・DVD

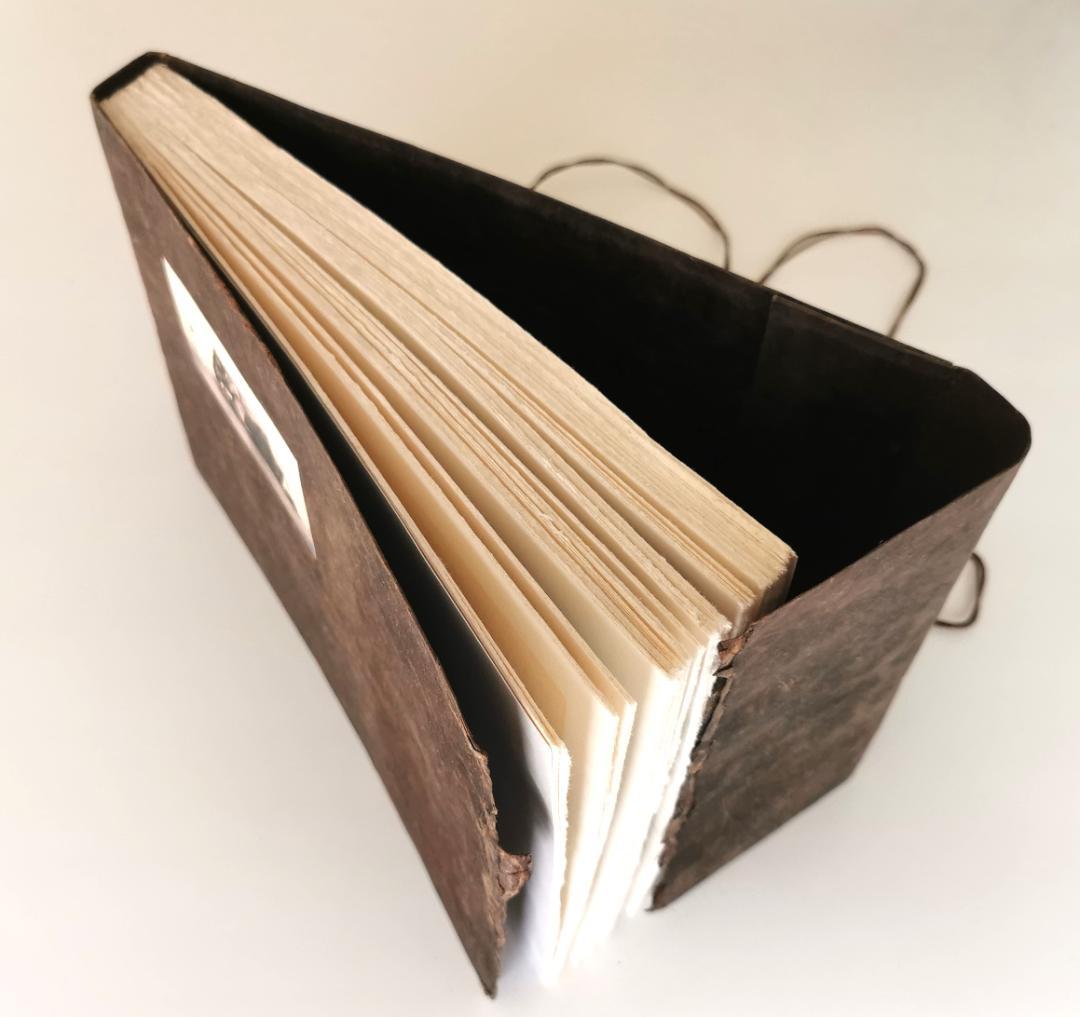

商品の説明Gregory Colbert グレゴリー・コルベール「Ashes and Snow」2007年にお台場の美術展で購入しました。長らく自宅保管しておりましたが、あまり見る機会がなく出品することにしました。写真集は中身はきれいなので鑑賞するには問題ありません。写真集のカバーはしわのある繊細な素材で痛みやすい装丁なので、多少ダメージがあります。DVDは未視聴、動作確認はしております。「the bird path」の短冊状のミニ写真集もお付けします。こちらはパラパラ漫画のような仕組みになっており、動きのある写真を楽しむことができます。素人による検品の為、細かい傷や破損、欠品等、見落とし・未確認の場合がございますので、購入前に写真にて状態を確認下さい。品質を重視される方、神経質な方のご購入はご遠慮ください。商品の情報カテゴリー本・雑誌・漫画 > 本 > アート・デザイン・音楽商品の状態やや傷や汚れあり発送元の地域東京都